86 17344894490

service@chalcoaluminum.com

- Aluminum Forgings for Rail Vehicles

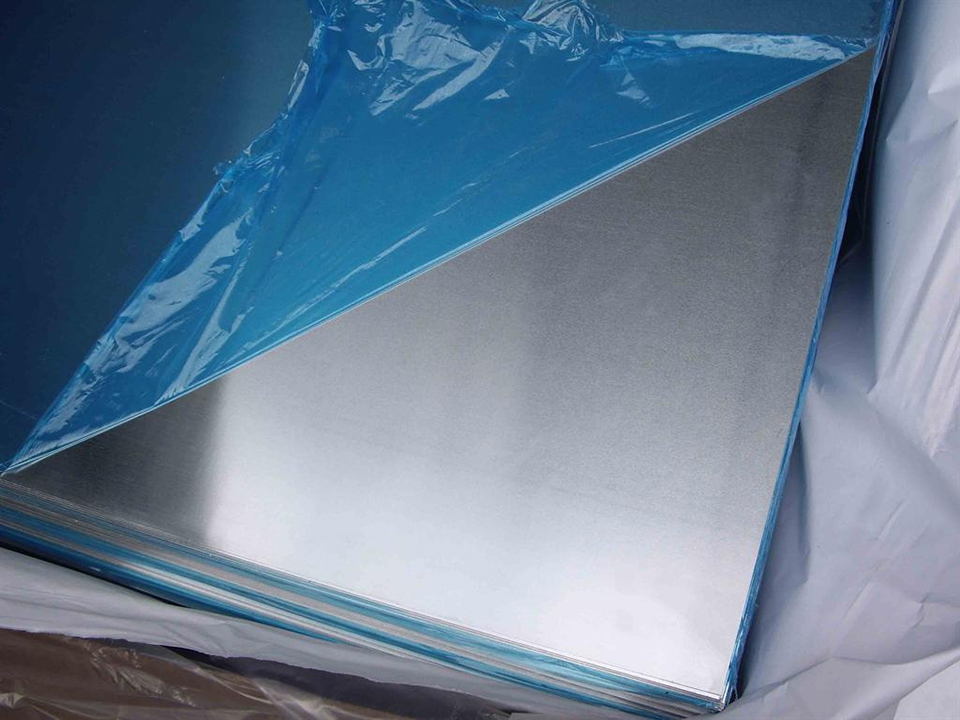

- Aluminum plate sheet for rail Rail vehicles

- Aluminum Profile for Rail Vehicles

6005A aluminum alloy profile extrusion

6005A aluminum alloy is an Al Mg Si wrought aluminum alloy developed in Europe. It has medium strength, good mechanical properties and corrosion resistance, good weldability and excellent hot extrusion properties. 6005A aluminum alloy can be extruded into various large aluminum alloy thin-walled plates, hollow and solid profiles with complex shapes. In foreign countries, 6005A aluminum alloy profile extrusion is usually used in the manufacture of traffic vehicles. By using advanced extrusion technology, 6005A aluminum alloy ingot can be extruded into large size wide profile. This profile is used to manufacture the body of high-speed railway vehicles and metro vehicles, which greatly reduces the weight of vehicles, improves the running speed of vehicles, and obtains better economic and social benefits

6005A aluminum alloy profile extrusion

6005A aluminum alloy has excellent extrudability, weldability, corrosion resistance and medium strength. It can extrude wide, flat and thin-walled hollow profiles with complex cross-section shape, and can realize on-line air cooling or water mist quenching on the extruder. It has been widely used in the manufacturing of rail transit vehicles.

Macrostructure test is one of the most routine and important test items for rail transit aluminum alloy profiles. In the process of high-speed operation of rail vehicles, low magnification structure defects will lead to serious consequences such as car body cracking. At present, there are few researches on bright line defects of 6005A aluminum alloy profile extrusion macrostructure used in rail transit at home and abroad. For 6005A aluminum alloy profile extrusion used in rail train, the uniformity of profile structure is required to be very high in high-speed operation of train, and the bright line of macrostructure is not allowed to appear.

The difference of local aluminum flow velocity in extrusion process is the reason for the appearance of macrostructure bright line in large and complex section profile.

On the high-power metallography, the bright line of low-power structure shows that the grain structure is obviously disordered and disordered, and the normal structure on both sides shows a relatively obvious ordered slender extrusion structure.

The friction between the aluminum alloy and the inlet of the guide die is increased by repairing the die, and the baffle at the die surface is increased to balance the hydrostatic pressure of each part, so as to ensure the stability of each part

The bright line defect of 6005A aluminum alloy macrostructure can be eliminated by uniform flow velocity.

Free offer of products, welcome to consult at any time, we will give the first reply.Our Email: